Selection of type of blades

Axelberg bandsaw blades are widely recognized as technically the most advanced bandsaw blade available.

Proper blade selection

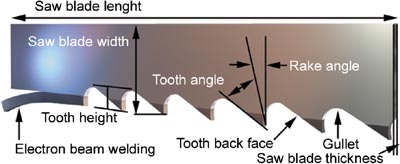

As a rule it is always best to use a blade with maximum possible width, since heavier feeding can then be used, due to the improved beam strength of the wider blade. On the other hand, the thickness is limited by the diameter of the wheels of the bandsaw machine.

Too small a diameter of the wheels in relation to the band’s thickness will cause band breakage.

Installation of band saw blades

Place the blade on the wheels and adjust to normal running position. Adjust the tension of the blade. Incorrect blade tension will result in great waste of blades. If possible use a tension gauge.

Most machine manufacturers will recommend the proper tension for their machines. The bandsaw machine should be adjusted to the blade.

The wheels should be aligned with the blade guides for proper tracking of the blade. It is very important that the guides and the rear bearings are kept in good condition and should be replaced as soon as they are worn.

Make sure that your wire brush (or equivalent) is in good working condition for cleaning of the tooth gullet.

Variable tooth, Bi-Metal blades

Blades with variable teeth have different tooth pitches on the same blade and are recommended for cutting tubing and structural material but can also be used for solid materials.

Standard (F) tooth

Standard (FV) variable tooth